- Mobile Fuel Stations

- Storage Tanks

- Fresh Oil Tank

- Pumps

- Storage Technology

- Urea AUS32

- Sales Percentage

- Used Oil Equipment

- Workshop Technology

- Lubrication Systems

- Forklift Attachments

- Rainwater Tank

-

Manufacturer

- Bauer - Südlohn

- Elaflex

- Flux

- GRACO

- Horn - Tecalemit

- Jessberger

- Kingspan

- Küco

- Mato

- Meva-Tec

- PIUSI

- Pressol

- Priorit

- Rietbergwerke

- Righetto Serbatoi

- Roth Werke

- RR-Industrietechnik

-

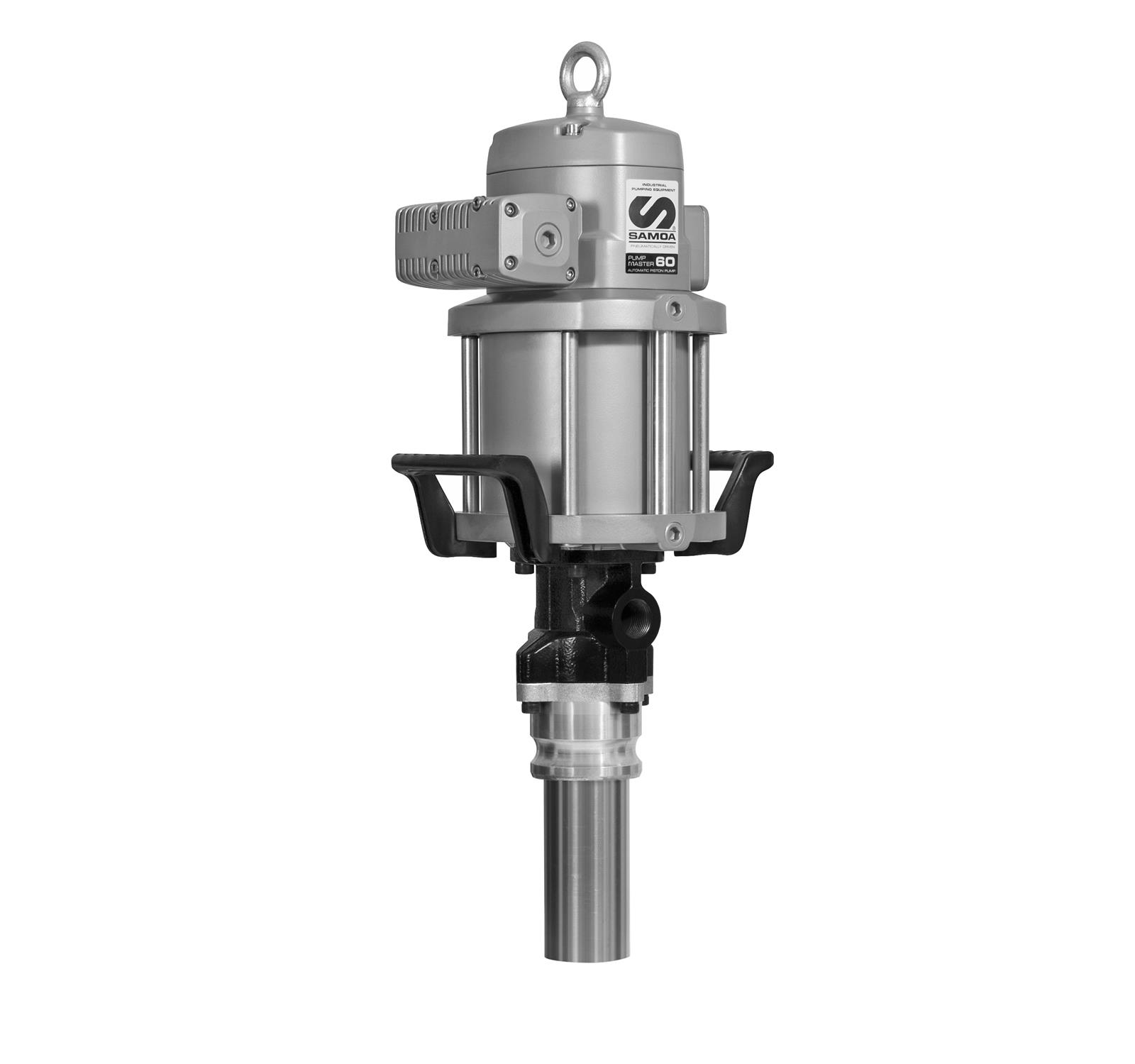

Samoa-Hallbauer

- AdBlue®

- Automatic Grease Guns

- Chemicals

- Dieselmatic

- Compressed Air Lubrication Equipment

- One-Handed Presses

- Liquid Management System

- Filling Equipment

- Filling Devices ZSA

- Manual Lever Press

- Compact Stereo System

- Plastic Tanks

- Storage

- Solvent Pumps

- Multipurpose Pumps

- Acid Measuring Container

- Measuring Jugs and Funnels

- The product category "Pumpmatic EZP" can be translated into natural, professional English as "Pumpmatic EZP Series."

- Vacuum and Filling Presses

- Hose Reel

- Grease Nipple

- Lubricant Dispenser

- Steel Tanks

- The term "Stosspressen" can be translated into English as "Forging Presses."

- Accessories

- Oil Equipment

- Schütz

- Swimer

- Tolsma Tanks

- MECLUBE

- Accessories

- Replacement Parts

Filter products

- For grease containers ranging from 15 to 50 kg

- Suitable for greases up to consistency class 2 (NLGI 2)

- Pressure capacity: 350 bar

- Delivery rate: approximately 2 g/stroke

- Suction tube length: varying between 300 and 660 mm

- Hand lever pump with: G 2" drum connection

- Equipped with a grease follower plate, dust protection cover with G 2" connection, 1.5 m grease hose with nozzle tube, and a professional 4-jaw coupler

- Pump tube diameter: 32 mm

Delivery time: 1-3 days

- Content: 16 kg

- Suitable for greases up to consistency class 2 and oils

- 3 lever settings for different delivery rates: 10 g, 15 g, 20 g per stroke

Delivery time: 1-3 days

- Processing: Greases up to consistency class NLGI 2

- Pressure Capacity: 500 bar

- Delivery Rate: 2 grams per stroke

- Capacity: 5 kg

- Hose Length: 2 meters

- Nozzle: Professional 4-jaw

Delivery time: 1-3 days

- Suitable for containers ranging from 10 to 185 kg

- For greases up to consistency class 2

- Transmission ratio of 1:55

- Double-acting for consistent grease flow

- Recommended compressed air range: 3 to 10 bar

- Compressed air connection: G 1/4" internal

Delivery time: 5-10 Tage

- For 25 kg fat bucket

- Transmission ratio 1:55 for high delivery rate

- Suitable for oils and greases up to consistency class 2, including bio-greases

- Grease follower plate and steel dust protection cover for optimal hygiene and safety

- Pneumatic connection G 1/4” internal, grease outlet G 1/4” internal

- Air pressure minimum 3 bar, maximum 10 bar; maximum lubrication pressure 400 bar

- Burst pressure 1,600 bar

- Delivery rate approximately 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter 30 mm

Delivery time: 5-10 Tage

- For grease containers from 18 to 200 kg

- Pumping capacity of 2 kg/min

- Pressure ratio of 3:1

- Air pressure from 2 to 10 bar

- Pump tube diameter of 34 mm

Delivery time: 5-10 Tage

- Transport Cart

- Compressed Air Connection G 1/4" internal

- Grease Outlet G 1/4" internal

- Maximum Lubrication Pressure: 400 bar

- Burst Pressure: 1,600 bar

- Air Pressure: Minimum 3 to Maximum 10 bar

- Air Consumption: 230 l/min

- Drum Fitting with 2" external thread

- Pressure Regulator and Water Separator for Reduced Wear Operation

- High Delivery Rate Due to 1:55 Gear Ratio

- Suitable for Oils and Greases up to Consistency Class 2, including Bio-Greases (Multi-Purpose Greases)

- Grease Follower Plate, Steel Dust Cover with Handle, 2 m Lubrication Hose

- High-Pressure Grease Gun with Ball-Bearing Professional Z-Joint, Particularly Easy to Operate Under Pressure

- Delivery Rate Approximately 550 g/min with Free Flow and 7 bar Inlet Pressure

- Pump Tube Diameter: 28 mm at the Top, 41 mm at the Bottom

Delivery time: 5-10 Tage

- For 15 / 18 kg fat containers

- Available with and without a trolley

- Compressed air connection G 1/4" i, grease outlet G 1/4" i

- Air pressure minimum 3 bar, maximum 10 bar

- Maximum lubrication pressure 400 bar

- Burst pressure 1,600 bar

- Delivery rate approximately 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter 30 mm

Delivery time: 5-10 Tage

- Grease Compatibility: Consistency Class 2

- Container Size: 12.5 – 20 kg

- Double-acting for consistent grease flow

- Recommended Air Pressure Range: 3 to 10 bar

- Transmission Ratio: 55:1

- Air Inlet Connection: G 1/4″i

- Grease Outlet: G 1/4″i

- Flow Rate: 550 g/min with free discharge and 7 bar inlet pressure

- Drum Fitting: 2″a-thread

- Suction Tube Length: 410 mm, Diameter: 26 mm

- Suction Tube with Foot Valve

- 2 m Delivery Hose 1/4″

- Grease Gun with Z-Joint

- Platform with Four Swivel Casters

Delivery time: 2-5 days

- For 20kg fat containers

- High delivery rate due to a gear ratio of 1:55, suction connection, and safety lubrication hoses with a large inner diameter.

- Suitable for oils and greases up to consistency class 2, including bio-greases.

- Equipped with a grease follower plate, steel dust cover, and high-pressure lubrication gun.

- Compatible with 25kg fat containers.

- Available as stationary (without trolley) or mobile (with trolley).

- Features a compressed air connection G 1/4” i and grease outlet G 1/4” i.

- Operates with a minimum air pressure of 3 bar and a maximum of 10 bar.

- The maximum lubrication pressure is 400 bar, with a burst pressure of 1,600 bar.

Delivery time: 5-10 Tage

- For 50kg grease container

- Compressed air connection: G 1/4” internal

- Grease outlet: G 1/4” internal

- Air pressure: min. 3 bar, max. 10 bar

- Lubrication pressure: max. 400 bar

- Burst pressure: 1,600 bar

- Delivery rate: approx. 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter: 30mm

Delivery time: 5-10 Tage

- Maximum Output Pressure: 600 bar (8,700 psi)

- Flow Rate: 900 g/min constant, 2 kg/min maximum

- Air Pressure Range: 2 to 10 bar

- Parts in Contact with Media: Cast Iron, Hard Chrome-Plated Steel, Steel, UHMWPE, NBR, PTFE, Viton

Delivery time: 2-5 days

- For 200 kg grease containers

- Suitable for oils and greases up to consistency class 2, including bio-greases

- Safety lubrication hoses up to 10 meters in length; optionally available with automatic hose reel

- Delivery rate of approximately 600 g/min with free flow and 7 bar inlet pressure

- Maximum lubrication pressure of 400 bar, burst pressure of 1,600 bar

Delivery time: 5-10 Tage

- Suction Tube Length: 516 mm, Diameter: 35 mm

- Maximum Delivery Rate: 2 kg/min

- Air Pressure Range: 1.5 to 10 bar

- Max. Output Pressure: 600 bar

Delivery time: 2-5 days

- Maximum Delivery Rate: 2 kg/min

- Air Connection: G 3/8″i

- Outlet Thread: G 3/8″i

- Air Pressure Range: min. 1.5 to max. 10 bar

- Max. Outlet Pressure: 600 bar

Delivery time: 2-5 days

- Suction Tube: 516 mm long, ø 35 mm

- Maximum Delivery Rate: 2 kg/min

- Air Pressure Range: 1.5 to 10 bar

- Max. Output Pressure: 600 bar

Delivery time: 2-5 days

- Max. Delivery Rate: 2 kg/min

- Air Connection: G 3/8"i

- Output Thread: G 3/8"i

- Max. Output Pressure: 600 bar

- Air Pressure Range: min. 1.5 to max. 10 bar

Delivery time: 2-5 days

- Maximum Delivery Rate: 2 kg/min

- ø Air Motor: 80 mm or 3.15″

- Air Connection: G 3/8″ internal

- Output Thread: G 3/8″ internal

- Air Pressure Range: min. 1.5 to max. 10 bar

- Maximum Output Pressure: 600 bar

Delivery time: 2-5 days

- Suitable for 12.5 – 20 kg containers

- Maximum delivery rate: 2 kg/min

- Suction tube: 516 mm long, ø 35 mm

- Air pressure range: 1.5 to 10 bar

Delivery time: 2-5 days

Delivery time: 2-5 days

Delivery time: 2-5 days

Delivery time: 2-5 days

Samoa Pneumatic Lubrication Equipment – Efficient & Powerful Lubrication with Air Pressure

Pneumatic lubrication equipment from Samoa provides quick, uniform, and clean lubricant delivery for professional applications. Whether in workshops, mechanical engineering, or agriculture, these devices ensure reliable maintenance and extended lifespan of your equipment.

Why Choose Samoa Pneumatic Lubrication Equipment?

- High Working Pressure: Suitable for use with grease or high-viscosity lubricants.

- Consistent Delivery Rate: Ideal for intensive lubrication cycles and routine maintenance.

- Robust Construction: Resistant to wear and tear in daily workshop use.

- Compatible with Large Containers: Direct lubrication from 12, 20, 50, or 200-liter drums is possible.

Typical Applications

- Commercial Vehicle & Agricultural Machinery Maintenance: Centralized supply to hard-to-reach lubrication points.

- Industry & Mechanical Engineering: Continuous lubrication during the production process.

- Automotive & Commercial Vehicle Workshops: Time savings in the maintenance of entire fleets.

Available Models & Accessories

- Pneumatic Lubrication Equipment with Hose Reel or Mobile Cart

- Grease Dispensing Systems with Metering Gun & Pressure Regulator

- Accessories: Hoses, Couplings, Grease Distributors & Retrofit Kits

Discover Samoa Pneumatic Lubrication Equipment Now

Optimize your lubrication processes with high-performance pneumatic lubrication equipment from Samoa for maximum efficiency and reliability!