Filter products

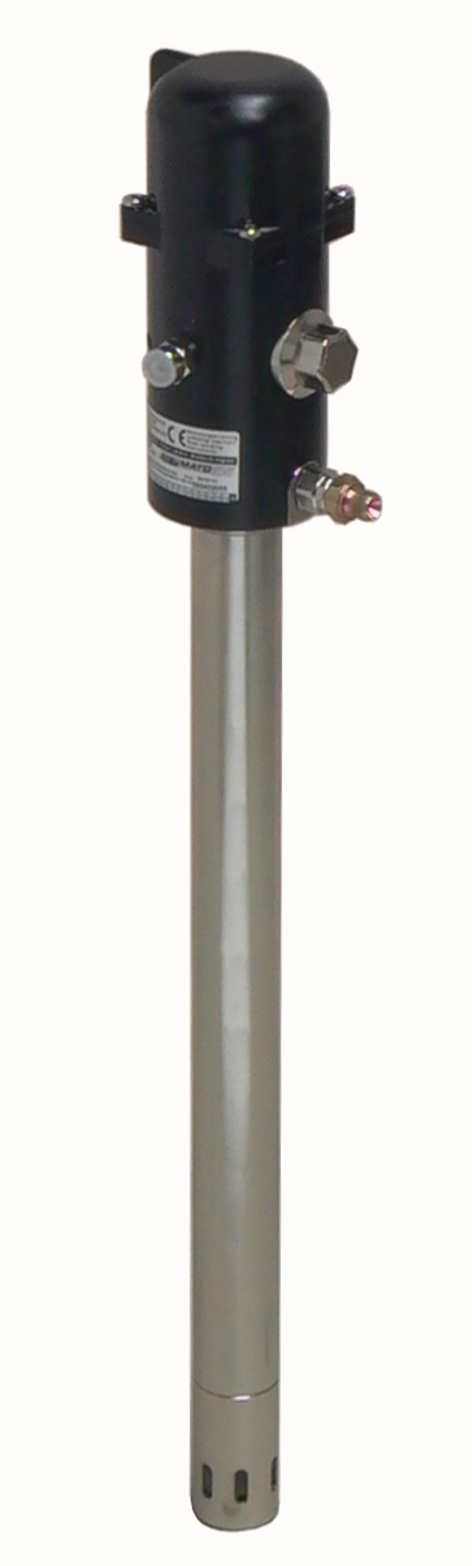

- Drum size: 18 to 200 kg

- Compression ratio: 60:1

- Air pressure: 4-7 bar

- Air consumption: 130-160 l/min

- Air inlet connection: F.1/4"

- Grease side connection: M.1/4"

- Suction line diameter: 30 mm

Delivery time: 5-10 Tage

- For 18/20 kg JOKEY plastic containers

- 2 m high-pressure safety armored hose with 4-jaw hydraulic gripping nozzle

- Includes centering lid with special holding claws for optimal attachment to the JOKEY container (Jet 2000)

- High-quality grease follower piston and robust suction tube with a diameter of 40 mm

- Operating pressure: 400 bar / 1.6 ccm/stroke

- Suitable for greases of NLGI class 000 - 2

Delivery time: 5-10 Tage

- Fat container capacity ranging from 10 to 200 kg

- Pressure ratio: 1:55

- Flow rate at free discharge: 500 g/min

- Maximum operating pressure: 425 bar

- Grease connection: R 1/4"

- Suction tube diameter: 40 mm

- Suitable for greases of NLGI grade 000-2

Delivery time: 5-10 Tage

- Suction Tube Length: 525mm, 790mm, 940mm, 1490mm

- Flow Rate: approximately 4,000 g/min at 8 bar inlet pressure

- Pressure Performance: approximately 24 bar

- Pressure Ratio: 1:3

- Connection Thread: R1/2"

Delivery time: 5-10 Tage

- Suitable for containers ranging from 10 to 185 kg

- For greases up to consistency class 2

- Transmission ratio of 1:55

- Double-acting for consistent grease flow

- Recommended compressed air range: 3 to 10 bar

- Compressed air connection: G 1/4" internal

Delivery time: 5-10 Tage

- Pressure Ratio: 60:1

- Suction Tube Length: 750 mm

- Drum Lid: Ø 420 mm

- Grease Follower Plate: Ø 400 mm

Delivery time: 2-5 days

- 1:1 Transfer Kit

- Suitable for 200-liter drums

- Compressed Air Pump "PumpMaster 2" DP-F 1:1

- Flow rate of 3 kg/min

- Filling gun, ball valve with angled outlet

- 3 m pressure hose, G 3/4"

Delivery time: 1-3 days

- For 25 kg fat bucket

- Transmission ratio 1:55 for high delivery rate

- Suitable for oils and greases up to consistency class 2, including bio-greases

- Grease follower plate and steel dust protection cover for optimal hygiene and safety

- Pneumatic connection G 1/4” internal, grease outlet G 1/4” internal

- Air pressure minimum 3 bar, maximum 10 bar; maximum lubrication pressure 400 bar

- Burst pressure 1,600 bar

- Delivery rate approximately 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter 30 mm

Delivery time: 5-10 Tage

- For 10kg to 200kg fat buckets

- NLGI grade 000 to 2

- Pneumatic unit

- High-pressure lubrication gun with linear swivel joint

- Nozzle tube with 4-jaw hydraulic gripping mouthpiece

Delivery time: 5-10 Tage

- ` and `

- ` tags:

```html

- Product Code: MC-013-1108-000

Delivery time: 2-5 days

- Pressure Ratio: 1:3

- Compatible with 10 to 200 kg grease buckets

- Flow Rate: approximately 4,000 g/min at 8 bar inlet pressure

- Pressure Output: approximately 24 bar

- Connection Thread: R1/2"

Delivery time: 5-10 Tage

- Pressure Ratio: 60:1

- Suction Tube Length: 750 mm

- Drum Lid Diameter: 395 mm

- Grease Hose Length: 4 m, Inner Dimension 1/4"

Delivery time: 2-5 days

- Fat container capacity: 15 to 50 kg

- Delivery rate: approximately 4,000 g/min at 8 bar inlet pressure

- Pressure output: approximately 24 bar

- Pressure ratio: 1:3

- Connection thread: R1/2"

Delivery time: 5-10 Tage

- For grease containers from 18 to 200 kg

- Pumping capacity of 2 kg/min

- Pressure ratio of 3:1

- Air pressure from 2 to 10 bar

- Pump tube diameter of 34 mm

Delivery time: 5-10 Tage

- Transport Cart

- Compressed Air Connection G 1/4" internal

- Grease Outlet G 1/4" internal

- Maximum Lubrication Pressure: 400 bar

- Burst Pressure: 1,600 bar

- Air Pressure: Minimum 3 to Maximum 10 bar

- Air Consumption: 230 l/min

- Drum Fitting with 2" external thread

- Pressure Regulator and Water Separator for Reduced Wear Operation

- High Delivery Rate Due to 1:55 Gear Ratio

- Suitable for Oils and Greases up to Consistency Class 2, including Bio-Greases (Multi-Purpose Greases)

- Grease Follower Plate, Steel Dust Cover with Handle, 2 m Lubrication Hose

- High-Pressure Grease Gun with Ball-Bearing Professional Z-Joint, Particularly Easy to Operate Under Pressure

- Delivery Rate Approximately 550 g/min with Free Flow and 7 bar Inlet Pressure

- Pump Tube Diameter: 28 mm at the Top, 41 mm at the Bottom

Delivery time: 5-10 Tage

- For 15 / 18 kg fat containers

- Available with and without a trolley

- Compressed air connection G 1/4" i, grease outlet G 1/4" i

- Air pressure minimum 3 bar, maximum 10 bar

- Maximum lubrication pressure 400 bar

- Burst pressure 1,600 bar

- Delivery rate approximately 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter 30 mm

Delivery time: 5-10 Tage

- for fat containers ranging from 10 kg to 200 kg

- pneumatic transfer pump with high delivery rate

Delivery time: 5-10 Tage

- Pressure Ratio: 1:55

- Flow Rate: 500 g/min with free discharge

- Max. Operating Pressure: 425 bar

- Suction Tube Diameter: 40 mm

Delivery time: 2-5 days

- For 20kg fat containers

- High delivery rate due to a gear ratio of 1:55, suction connection, and safety lubrication hoses with a large inner diameter.

- Suitable for oils and greases up to consistency class 2, including bio-greases.

- Equipped with a grease follower plate, steel dust cover, and high-pressure lubrication gun.

- Compatible with 25kg fat containers.

- Available as stationary (without trolley) or mobile (with trolley).

- Features a compressed air connection G 1/4” i and grease outlet G 1/4” i.

- Operates with a minimum air pressure of 3 bar and a maximum of 10 bar.

- The maximum lubrication pressure is 400 bar, with a burst pressure of 1,600 bar.

Delivery time: 5-10 Tage

- Drum Size: Suitable for 50-60 kg drums

- Suction Tube Length: 750 mm for deep immersion

- Drum Lid: Ø 420 mm for secure sealing

- Grease Hose: 1/4", 4 m length for extended reach

Delivery time: 2-5 days

- For 50kg grease container

- Compressed air connection: G 1/4” internal

- Grease outlet: G 1/4” internal

- Air pressure: min. 3 bar, max. 10 bar

- Lubrication pressure: max. 400 bar

- Burst pressure: 1,600 bar

- Delivery rate: approx. 600 g/min with free flow and 7 bar inlet pressure

- Pump tube diameter: 30mm

Delivery time: 5-10 Tage

- Delivery Rate: approximately 550 g/min

- Pressure Ratio: 55:1

- Suitable for Greases up to Consistency Class NLGI 2

- Air Pressure: minimum 3 to maximum 10 bar

Delivery time: 2-5 days

- Translation Ratio: 1:55

- Hose Length: 3.5 m

- High-Pressure Lubrication Hose: DN 6, R1/4"

- Suitable for Greases of NLGI Grade 000 - 2

Delivery time: 5-10 Tage

- For 10kg to 200kg fat buckets

- Pressure ratio: 1:75

- Flow rate with free discharge: 500 - 600 g/min

- Max. operating pressure: 580 bar

- Grease connection: R1/4"

- Suction tube diameter: 40 mm

- For greases of NLGI grade 000-2

- Conditionally possible up to NLGI grade 000-3

Delivery time: 5-10 Tage

Compressed Air Lubrication Devices – Consistent & Powerful Lubricant Supply

Compressed air lubrication devices provide precise, consistent, and powerful lubrication for machines, vehicles, and industrial facilities. They ensure efficient distribution of oil and grease, making them ideal for workshops, agricultural technology, and industrial maintenance.

Why Use Compressed Air Lubrication Devices?

- Consistent Lubricant Supply: Reduces wear and extends lifespan.

- Efficient & Economical: Even distribution minimizes lubricant consumption.

- High Operating Pressure: Perfect for demanding applications.

- Robust Construction: Designed for long-term use.

Types of Compressed Air Lubrication Devices

- Oil Lubrication Devices: Provides consistent oil supply for machines and engines.

- Grease Lubrication Devices: High-pressure lubrication for bearings and moving parts.

- Automatic Lubrication Devices: Program-controlled solutions for industrial applications.

- Mobile Compressed Air Lubrication Devices: Flexible for use in workshops and operations.

Find the Right Compressed Air Lubrication Device Now

Ensure professional and efficient lubrication – explore our compressed air lubrication devices for reliable lubricant supply!