Filter products

- Capacity: For 400 g cartridges or 500 g loose grease

- Connection thread: M10x1

- Operating pressure: over 400 bar

- Maximum pressure: up to approximately 1000 bar

Delivery time: 1-3 days

- Usable Content: 500 cm³ (or 400 g cartridges)

- Maximum Pressure Output: 400 bar

- Delivery Volume per Stroke: up to 2 cm³

- Connection Thread: M 10x1 IG

Delivery time: 1-3 days

- Usable Content: for 500 g screw cartridges

- Pressure Performance: max. 400 bar

- Length without Connection: 320 mm

- Weight: 1.08 kg

- Delivery Volume/Stroke: up to 2 cm³

- Connection Thread: M 10x1 IG

Delivery time: 1-3 days

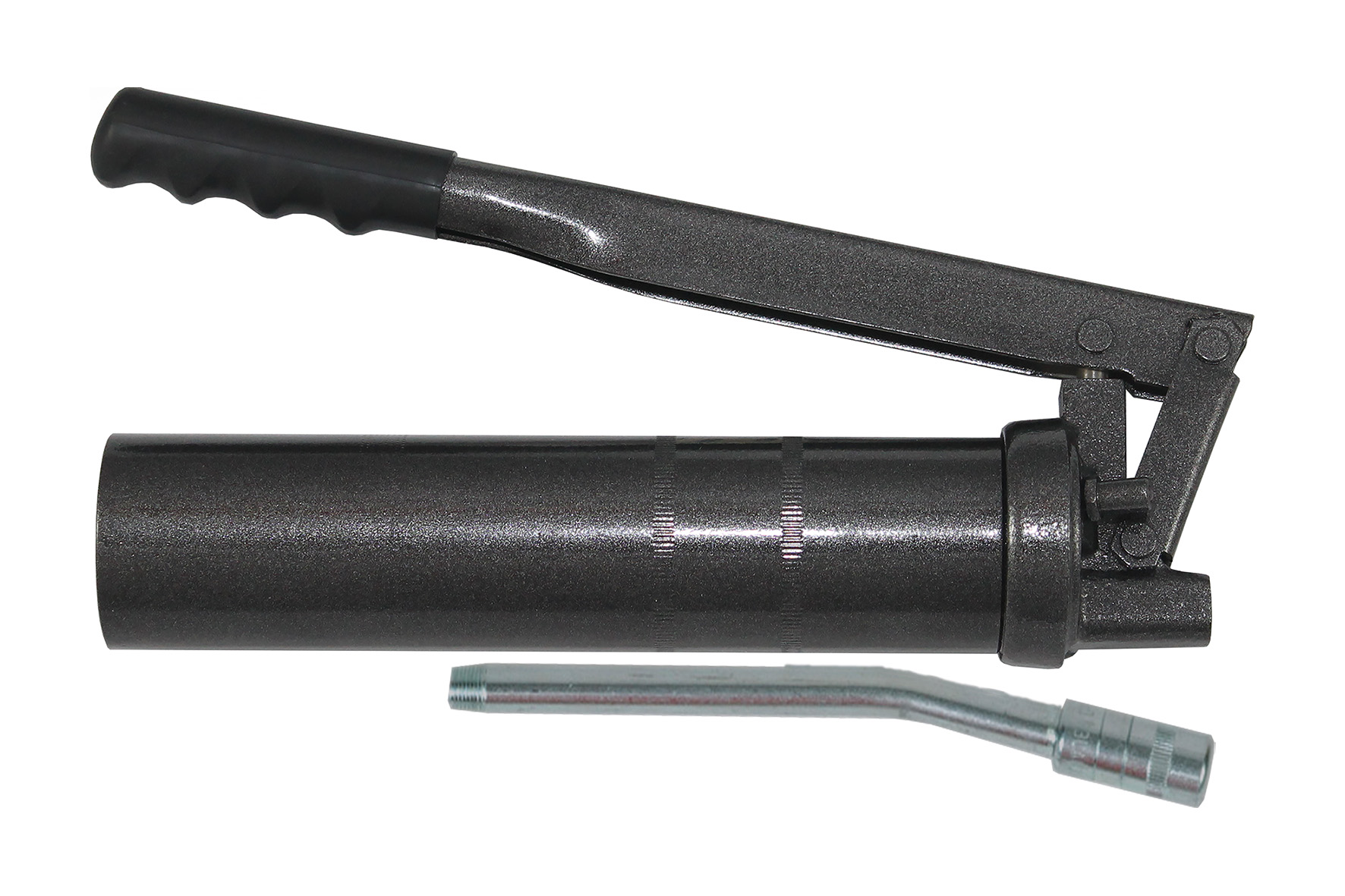

- All-steel lever grease gun with base seal

- Capacity: 600 ccm

- Connection thread: M10x1

Delivery time: 1-3 days

Average rating of 5 out of 5 stars

- for Lube-Shuttle® system

- Connection thread: M10x1

- Grease container: Galvanized – robust & durable

- Peak pressure: up to approximately 800 bar

Delivery time: 1-3 days

- Delivery Rate: Approximately 1 cm³ per stroke

- Capacity: 500 cm³ / 400 g

- Connection Thread: M 10 x 1 or G 1/8"

Delivery time: 2-5 days

- Compatible with 500 g screw cartridges "System Reiner"

- Operating pressure: 400 bar

- Maximum pressure: up to 800 bar

Delivery time: 1-3 days

- Content: 500 cc / 400 g

- Connection Thread: M 10 x 1

- Delivery Rate: approx. 1 cc/stroke

- Material: Steel, robust and durable

Delivery time: 2-5 days

- Content: 500 ccm / 400 g

- Includes nozzle tube

- Includes 4-jaw mouthpiece

Delivery time: 2-5 days

Average rating of 5 out of 5 stars

- for Lube-Shuttle® system

- Connection thread: M10x1

- Pressure performance: approx. 400 bar

Delivery time: 1-3 days

- for Lube-Shuttle® system

- Connection thread: M10x1

- with nozzle tube & grease cartridge

- Grease container: Galvanized – robust & durable

- Operating pressure: over 400 bar

- Maximum pressure: approx. 800 bar (tested by TÜV, DLG, BLT)

Delivery time: 1-3 days

- Filling Volume: 500 ccm / 400 g

- Connection Thread: M10 x 1

- Additional Features: Filling Nipple

- Filling Methods: "Fillmaster" or 400 g Grease Cartridges (DIN 1284)

Delivery time: 1-3 days

- Contents: 500 ccm / 400 g

- Includes safety rubber armored hose

- Includes 4-jaw nozzle

Delivery time: 2-5 days

Average rating of 5 out of 5 stars

- for Lube-Shuttle® system

- Connection thread: M10x1

- Includes hose & grease cartridge

- Grease container: Galvanized – robust & durable

- Operating pressure: over 400 bar

- Maximum pressure: approx. 800 bar (tested by TÜV, DLG, BLT)

Delivery time: 1-3 days

- Suitable for: 400 g screw-in cartridges

- Connection thread: M 10 x 1

- Burst pressure of the rubber armored hose: 1,600 bar

- Material: Steel

Delivery time: 2-5 days

- Volume: 500 cm³ or 400 g

- Material: High-quality precision steel with die-cast zinc head

- Connection thread: M 10 x 1 or G 1/8″i

- Burst pressure of safety rubber armored hose: 1,600 bar

Delivery time: 2-5 days

- ✅ Working pressure: 400 bar, maximum pressure > 800 bar; pressure gauge 0–400 bar

- ✅ Connection thread: R1/8"

- ✅ Capacity: 400 g cartridges or 500 g bulk grease

- ✅ Short-stroke system with stepless piston rod locking (permanent spring load)

- Professional Lever Press "X-TRA 701"/M

- Safety Rubber Armored Hose 2200 with 4-Jaw Professional Nozzle and Quick-Change Coupling

- Nozzle Tube 103/M (DIN 1283), curved, with 4-Jaw Professional Nozzle

- Nozzle Tube 2060 with Universal Joint Nozzle and Quick-Change Coupling

- Nozzle Tube 2070/M1 with Slide Coupling for Flat Grease Nipples M1 ø 16 mm and Quick-Change Coupling

- Universal Nozzle 36/M

- Pointed Nozzle 23/M

Delivery time: 5-10 Tage

- Capacity: 16kg

- Discharge pipe for lubricating grease

- Includes carrying handle

Delivery time: 1-3 days

- For 5 kg buckets

- Bucket inner diameter: 156-206 mm

- Flow rate: approximately 50 cm³/stroke

- Pump tube diameter: 40 mm

Delivery time: 5-10 Tage

- For a 10 kg bucket of grease

- Bucket inner diameter: 200-236 mm

- Delivery rate: approximately 50 cm³/stroke

- Pump tube diameter: 40 mm

Delivery time: 5-10 Tage

- for 20 kg bucket of grease

- Bucket inner diameter: 260-306 mm

- Delivery rate: approximately 50 cm³/stroke

- Pump tube diameter: 40 mm

Delivery time: 5-10 Tage

- Suitable for grease containers ranging from 5 to 50 kg

- Includes a follower plate, dust protection cover, and a 2-meter PVC grease hose with a nominal width of 16, reinforced with nylon

- Self-closing quick coupling

- Can be used with or without a trolley

- Delivery rate of approximately 30 ccm per stroke

- Pump tube diameter of 40 mm

- Maximum operating pressure of 35 bar

Delivery time: 1-3 days

- For 50 kg bucket of grease

- Bucket inner diameter: 340-393 mm

- Delivery rate: approximately 50 cm³/stroke

- Pump tube diameter: 40 mm

Delivery time: 5-10 Tage

Grease Guns & Lubrication Devices – Precise Lubrication for Maximum Longevity

Grease guns and lubrication devices provide precise, clean, and powerful lubrication for bearings, joints, and machine components. They are essential for workshops, agriculture, construction, and industry.

Why Use a Grease Gun or Lubrication Device?

- Accurate Lubricant Delivery: Precise dosing for optimal lubrication.

- Reduced Wear: Extends the lifespan of machines and vehicles.

- Flexible & Versatile: Various models to meet different needs.

- Ergonomic Handling: Easy operation for comfortable use.

What Types of Grease Guns & Lubrication Devices Are Available?

- Manual Grease Guns: Cost-effective solution for simple applications.

- Battery-Powered Grease Guns: Cordless mobility for convenient operation.

- Pneumatic Grease Guns: Powerful high-pressure lubrication.

- Lubrication Devices with Hose: Precise application even in hard-to-reach areas.

Find the Right Grease Gun or Lubrication Device Now

Ensure professional and efficient lubrication – explore our grease guns and lubrication devices for reliable lubricant supply!